4. Diesel fuel storage tank(s):

The fuel oil in any storage tank (and day tank, if used) shall be tested in accordance with Clause 11.5.5, and if the

fuel oil fails the test, it shall be

(a) drained and refilled with fresh fuel in accordance with Article 6.5.1.5 of the National Fire Code of Canada; or

(b) full filtered to remove water, scale, bacteria, and oxidized gums/resins in order to minimize filter clogging

and ensure diesel start-up (see Clause B.24 for commentary).

When the fuel is filtered, it shall be treated with a suitable conditioner and stabilizer to minimize degradation while

in storage.

Note: The bottom(s) of the tank(s) shall be also tested chemically for water.

5. Generator:

(a) Test surge suppressor and rotating rectifier on brushless machines.

(b) Grease bearings (replace old grease with new) (if applicable).

(c) Clean commutator and slip rings (if applicable).

(d) Clean rotor and stator windings using clean compressed air.

(e) Inspect coupling bolts and alignment.

(f) Inspect conduits for tightness.

(g) Inspect windings at rotor and stator slots.

(h) Inspect all electrical connections.

(i) With the generator set operating at full load (see Clause 11.3), conduct an infrared survey of all electrical

connections to identify any high-resistance connections.

6. Overcurrent protective devices

(a) Electrically isolate all overcurrent protective devices.

(b) Remove all dust.

(c) Test devices for proper operation.

(d) While performing the full load test required by Clause 11.3, conduct an infrared survey of all electrical connections, contacts, and energized components.

7. Transfer switches:

(a) Isolate transfer switch, open all inspection covers, and inspect all electrical connections.

(b) Operate all moving parts to ensure that they move freely.

(c) Clean and dress contacts as required.

(d) Remove all dust.

(e) Clean and lubricate linkages.

(f) Conduct an infrared survey of all electrical connections, contacts, and energized components while under

load on both the normal and the emergency side.

8. Lubricate door locks and hinges (if necessary), especially those of outdoor enclosures.

9. Conduct a 2 h full-load test (see Clause 11.3).

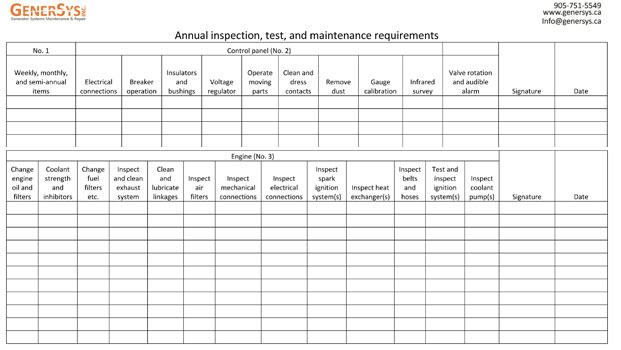

10. As needed, review and provide instruction on the technical requirements specified in Table 2, Table 3, and Table 4. with the

person(s) responsible for carrying out the work.

11. Correct all defects found during inspections and tests.

12. Record all inspections, tests, and corrective actions in the log (see Clause 11.5.3).